Precision for Machine Engineering

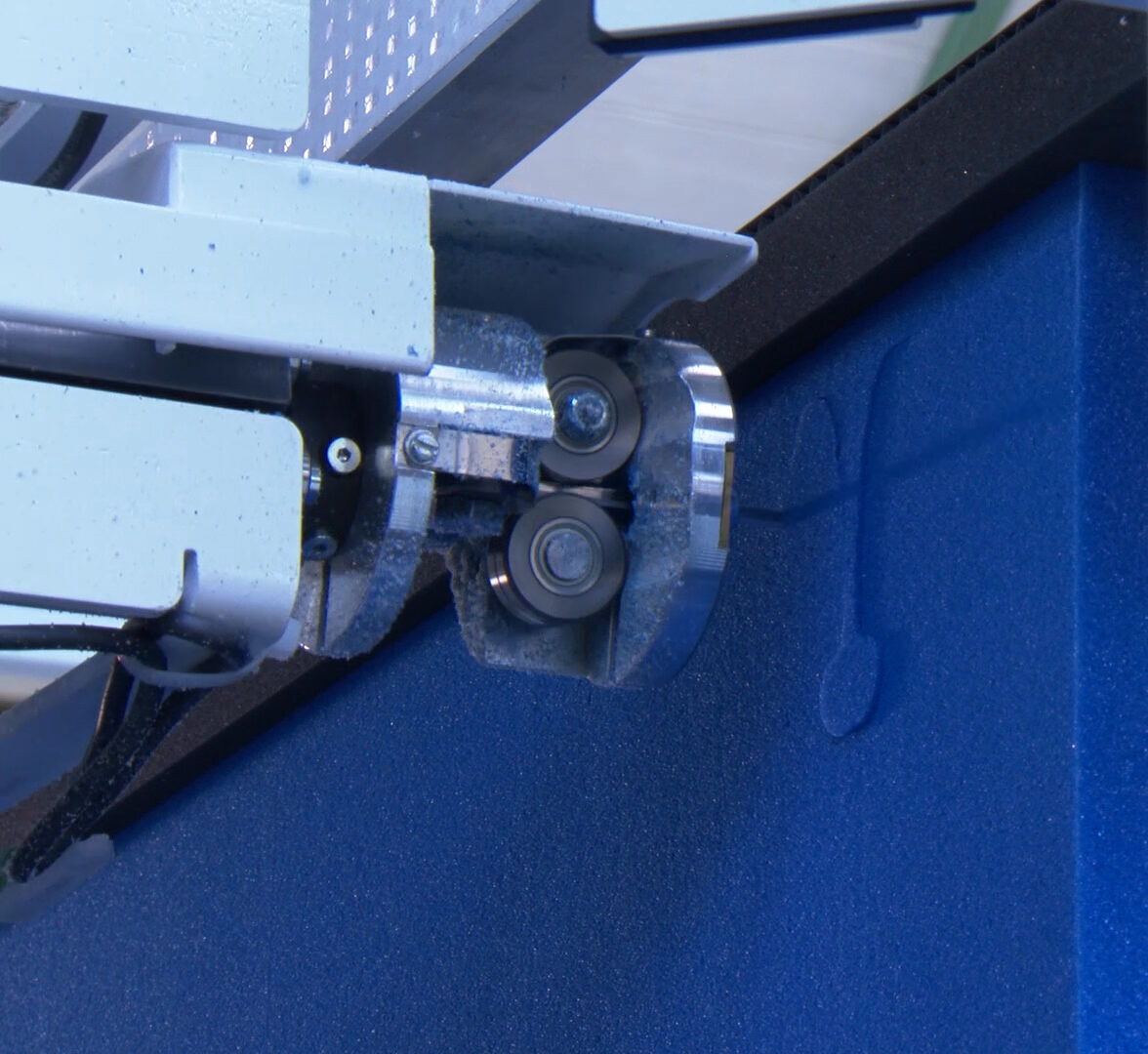

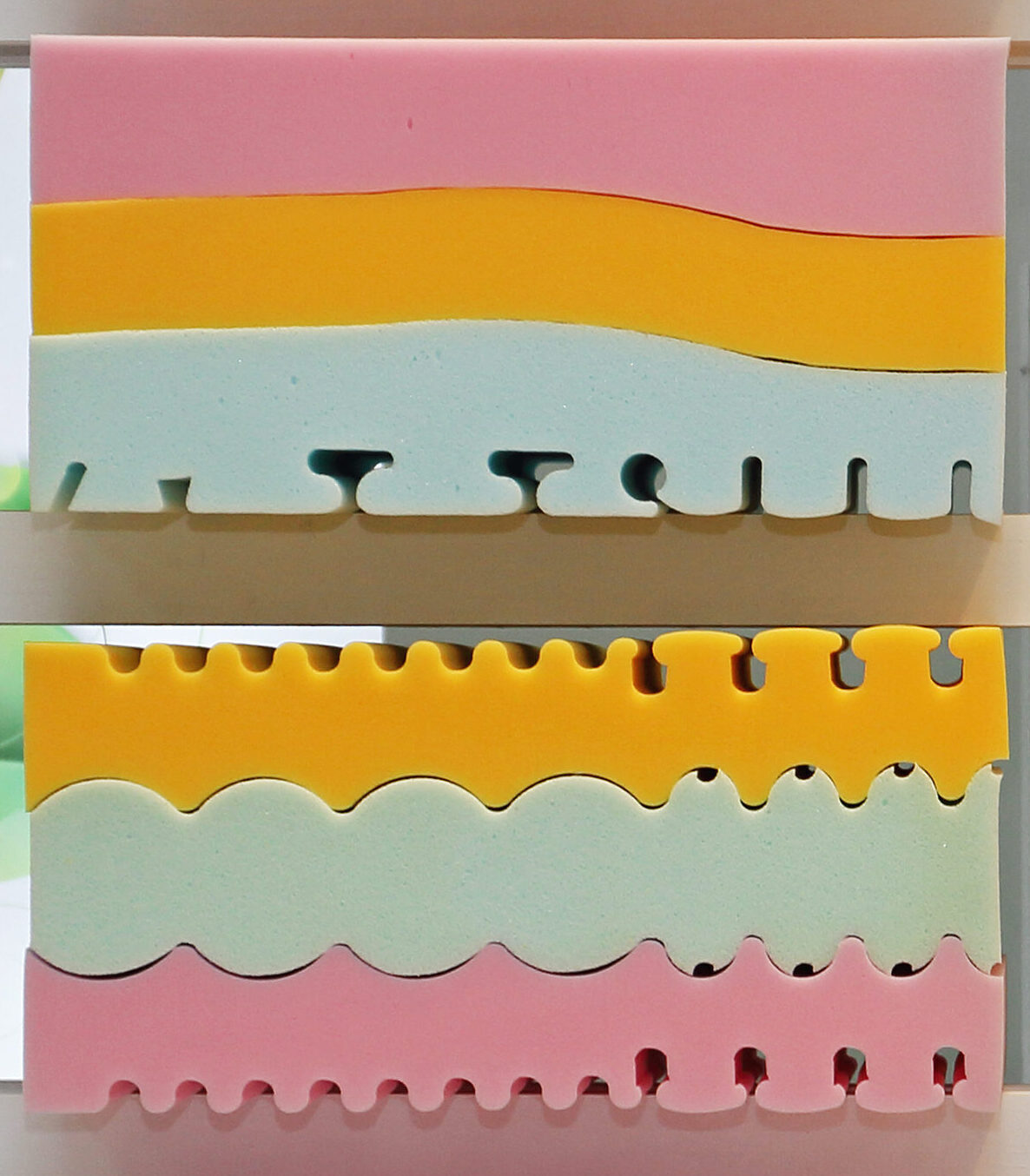

Whether in upholstery and mattress manufacturing or the packaging and automotive industry – worldwide Fecken-Kirfel's customers are convinced by the control solution, which guides the revolving band knife with optimal material utilisation, highly precise cutting guidance, and maximum speeds. Discover the CNC control solution tailored to the requirements of 2.5D contour cutting with special algorithms.

The Control Solution's Highlights

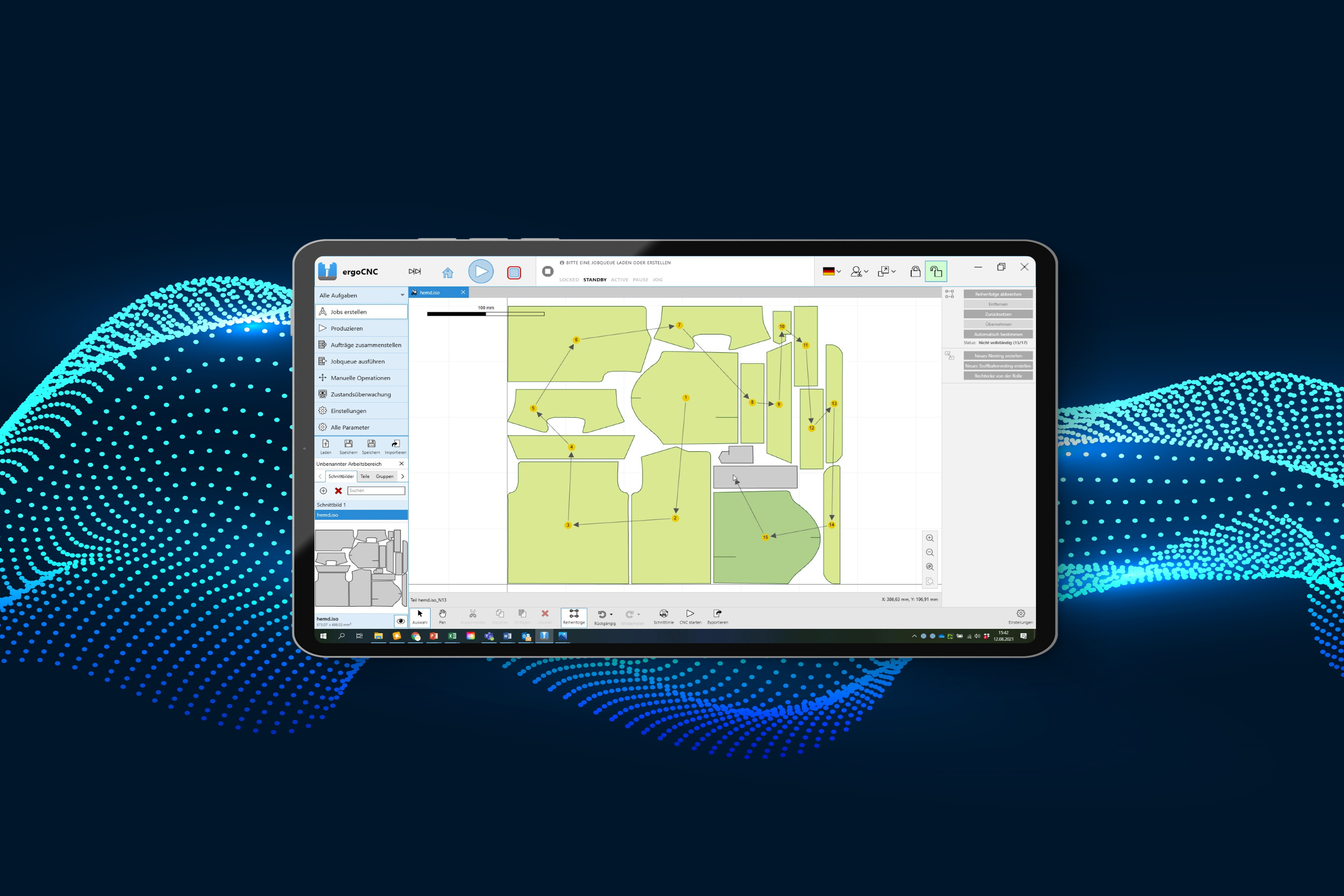

- Nesting and Routing with ergoCAM for optimal material utilisation and cutting line generation

- 2.5D cutting

- Fully automated or manual material transfer

- Automatic knife resharpening

- Knife guidance outside the contour

- Resuming after knife breakage within the material

- Automatic fixation of the block

- Material-specific speed regulation

- Integration into production lines via OPC UA

- Job Queue to prevent downtimes

- OPC UA Interface for gathering operational data and integrating the machine into prouction processes

- Integrated IIoT production monitoring with Clouver

In ProCom, we have found a partner who has been supplying us with a first-class CNC control solution for decades, who reliably supports the evolution of our machines, and who is committed to our high quality objectives.

In Action: Band Knife Cutting With the CNC300 Control Solution

Take a look at the ergoCNC control solution in use at our customer:

FUTHER DISCOVER THE VARIETY OF PROCOM CONTROL SOLUTIONS

This might also be of interest to you

Patrick Beer

Sales Manager IIoT

More Information? Reach Out to Us!

Learn more about our products, services, and potential collaboration. Simply get in touch with us by phone or email. I look forward to a personal exchange!

- Phone: +49 241 93681-500

- Email: contact@procom-automation.de