Precision and Productivity United

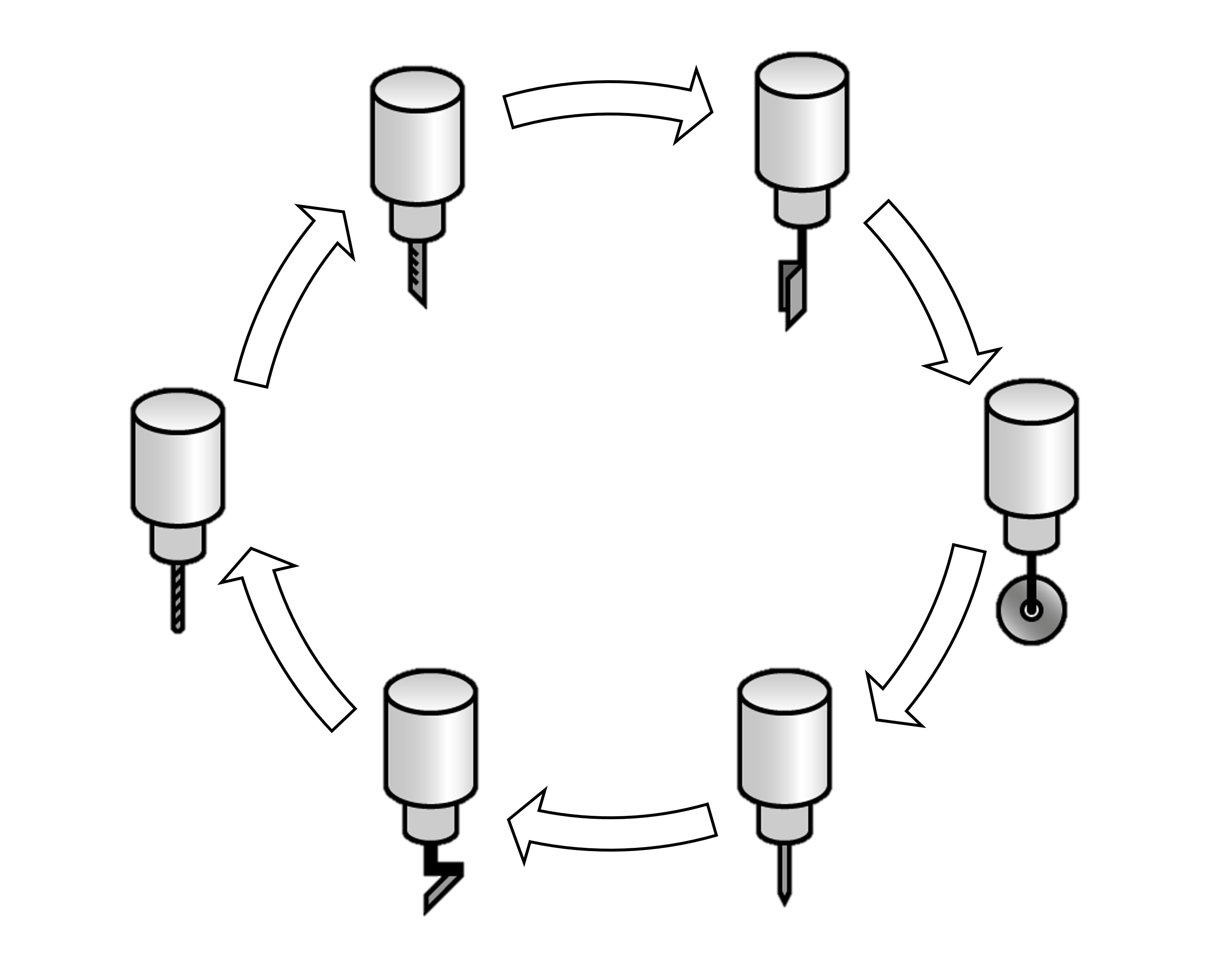

Whether you're cutting carbon, leather, steel, or foam – the ergoCNC and ergoCAM software of ProCom's CNC300 control solution excel with perfect precision and maximum cutting speed for all materials. The tailored algorithm for coordinated multi-axis movements, along with technology-specific functionalities, elevates all types of cutting machines to peak performance. The result: cutting outcomes that impress along the entire cutting line, whether it's knife, waterjet, laser, or plasma cutting.

The Cutting Dream Team

The CNC300 control solution includes CNC and CAM software:

ergoCNC

Reduced workload during the cutting process thanks to fully automatic job processing.

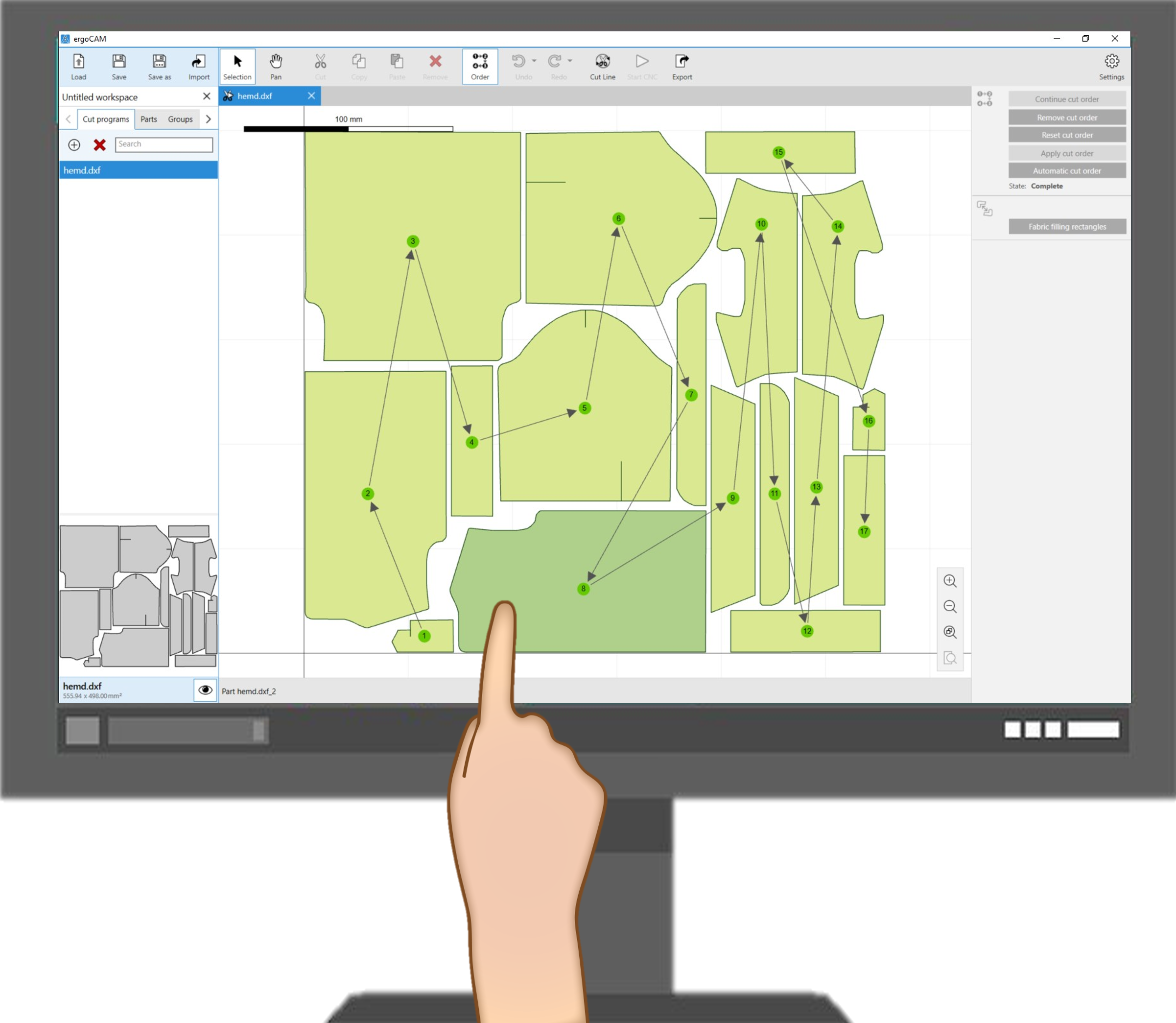

ergoCAM

User-friendly job preparation and resource-efficient job planning for a seamless workflow.

Smart and Intuitive Usability

The user-friendly interface of ergoCNC allows you to intuitively adjust all production parameters without the need for extensive training. Numerous specific functionalities ensure optimal cutting results – for every material and cutting technology. All functions can be operated both via the touchscreen and with a mouse and keyboard. Task-oriented and role-specific settings provide a clear layout, presenting you only with the information and controls needed for your current task.

Tool Management Made Easy

The Material Assistant allows you to quickly and intuitively select the optimal tool for any type of material. Parameter switching occurs fully automatically based on the values stored for the new tool. A signal icon indicates if parameter changes or a material-induced tool change is required. Thus, even inexperienced operators can manage the tools with ease in shortest time.

Your Benefits With the CNC300 Software

Highest Precision

Even with complex patterns and demanding cutting tasks, the software delivers to you reliable results with convincing accuracy thanks to its optimised algorithms.

Intuitively Designed Throughout

The user-friendly interface makes the software very effective, time-saving, and quickly learnable for all users.

Customisability

Upon request, our experts tailor the control software to your individual needs and collaborate with you to develop the functionalities that fully leverage the productivity potential of your equipment.

Efficient and Cost-Effective

The control software realises maximum cutting speeds – whether you are cutting metal, fabrics, tiles, carbon, or other materials.

Integration Into Other Systems

Our controls feature an OPC UA interface for data acquisition and integrating your machine into production processes.

Always by Your Side

The ProCom expert team is always available to support you personally with commissioning, technical questions, or training.

CNC300 Software in Action

Here, you get a glimpse of the ergoCNC software – Application example Textile Cutting:

EXPLORE OTHER COMPONENTS OF THE CONTROL SOLUTION AS WELL

Yatai Ji

Key Account Manager

More Information? Reach Out To Us!

Learn more about our CNC300 software products and potential collaboration. Simply get in touch with us by phone or email. I look forward to a personal exchange!

- Phone: +49 241 93681-500

- Email: contact@procom-automation.de