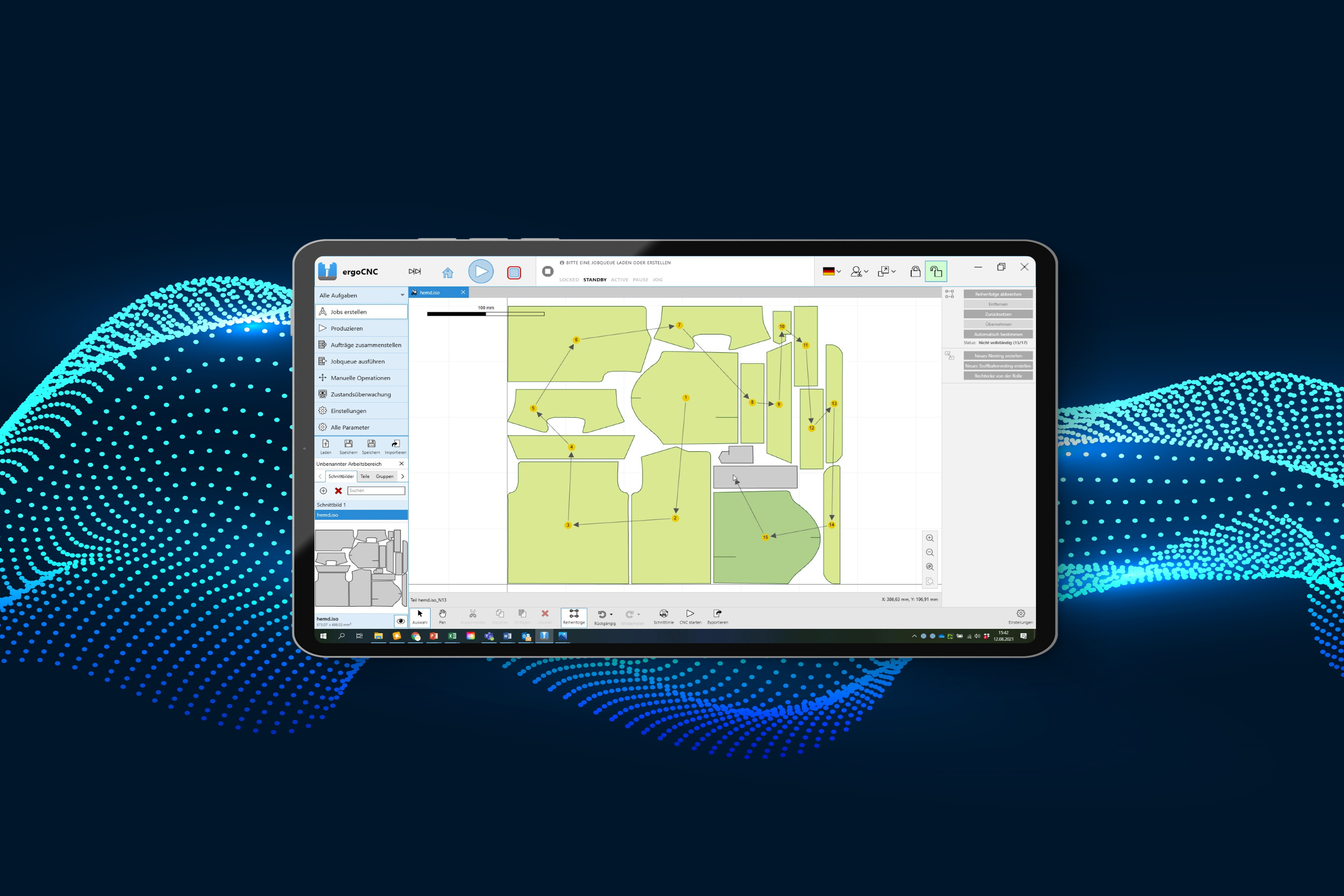

Our Products for Your Cutting Machines

As a machine builder and operator of cutting machines with ProCom control solutions, you benefit from an all-in-one package by a single source, comprising CNC and CAM software with matching hardware and fitting drive technology.

Sergej Gigel

Senior Sales Manager

More Information? Reach Out to Us!

Learn more about our CNC control products and potential collaboration. Simply get in touch with us by phone or email. I look forward to a personal exchange!

- Phone: +49 241 93681-500

- Email: contact@procom-automation.de