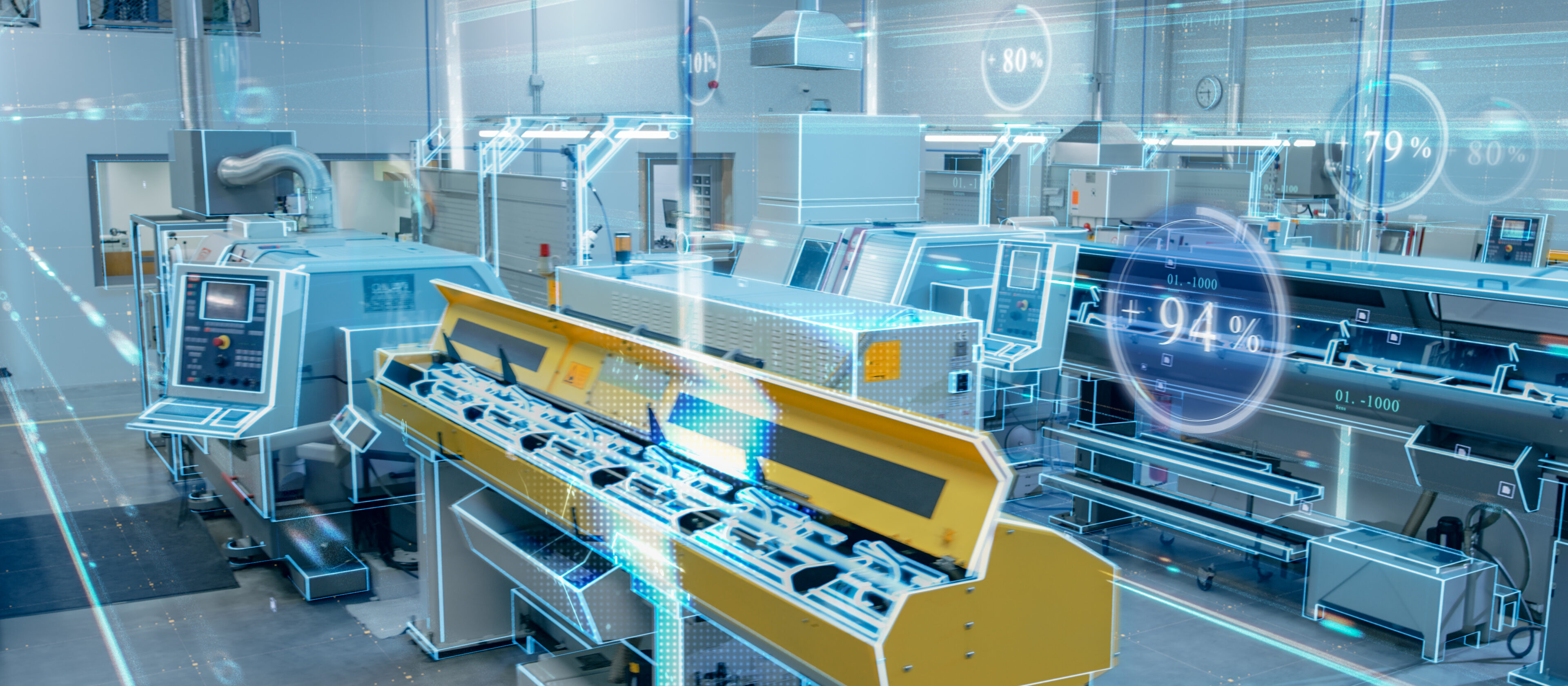

Your Custom IIoT Toolbox

With Clouver, you have access to a variety of flexible and well-thought-out tools for machine monitoring. Whether your company is already established, seeking ways to maximise productivity, or an emerging production facility in search of innovative solutions, Clouver is your solution.

From this extensive IIoT toolbox you choose the tools that precisely match your preferences and requirements. As a production manager and/or machine operator, this allows you to streamline your work and take the crucial step towards achieving an efficient, transparent, and profitable production.

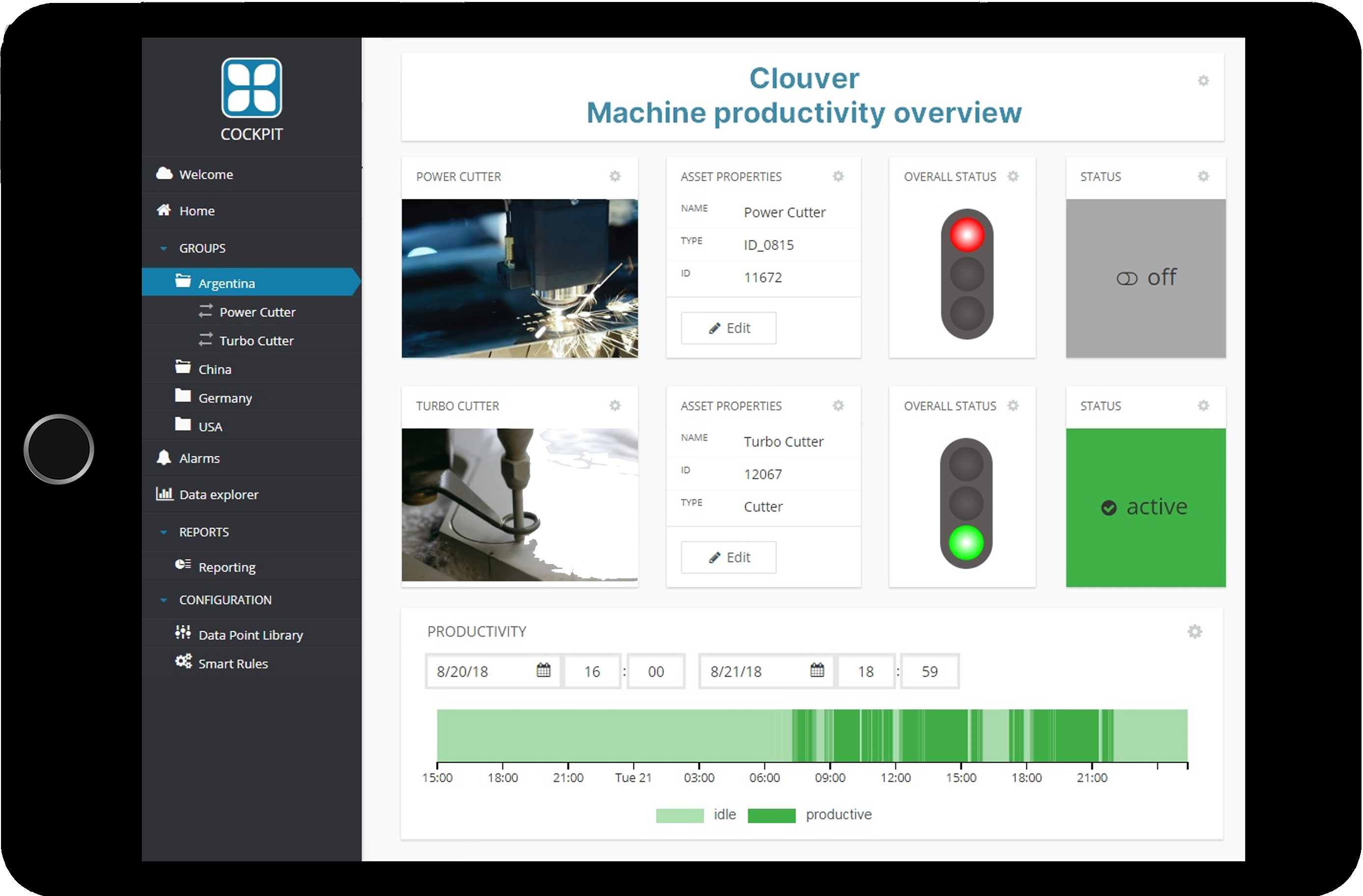

The Clouver Platform

On the Clouver platform dashboards, you consistently have access to real-time data from your production – no matter where you are! This enables you to promptly respond to downtimes or optimisation needs in your production chain, fostering sustainable productivity growth.

Flexible Components for Your Custom Demands

Clouver is modularly designed in both hardware and platform software functions. This ensures you will find the optimal solution for every requirement. You select precisely the functions you need for your individual use case – neither more nor less. Perfect flexibility.

Find out more about Clouver at first hand

Sergej Gigel

Senior Sales Manager

More Information? Reach Out to Us!

Learn more about our Clouver products and potential collaboration. Simply get in touch with us by phone or email. I look forward to a personal exchange!

- Phone: +49 241 93681-500

- Email: contact@procom-automation.de