Connectivity Without Borders: All Machine Data at a Glance

With Clouver, you connect all machines throughout your entire production chain. You receive real-time information from all machines, including performance metrics, reasons for downtime, production quantities, and more. Utilising key performance indicators and charts, you identify areas for optimisation. Accessible anytime and from anywhere, you monitor and compare all your machines, production lines, and facilities. This elevates your production to a new level of efficiency, achieving a sustainable increase in profitability.

A Single IIoT Platform, Countless Benefits for You

Easy Start, Significant Impact

Your machine is typically connected to Clouver in less than an hour. This applies to new and old ones, as well as even to manually operated workstations – all of them without costly retrofits. Consequently, you gain insight into your entire production from anywhere in the world within a few hours, with the ability to compare all your machines, production lines, and facilities.

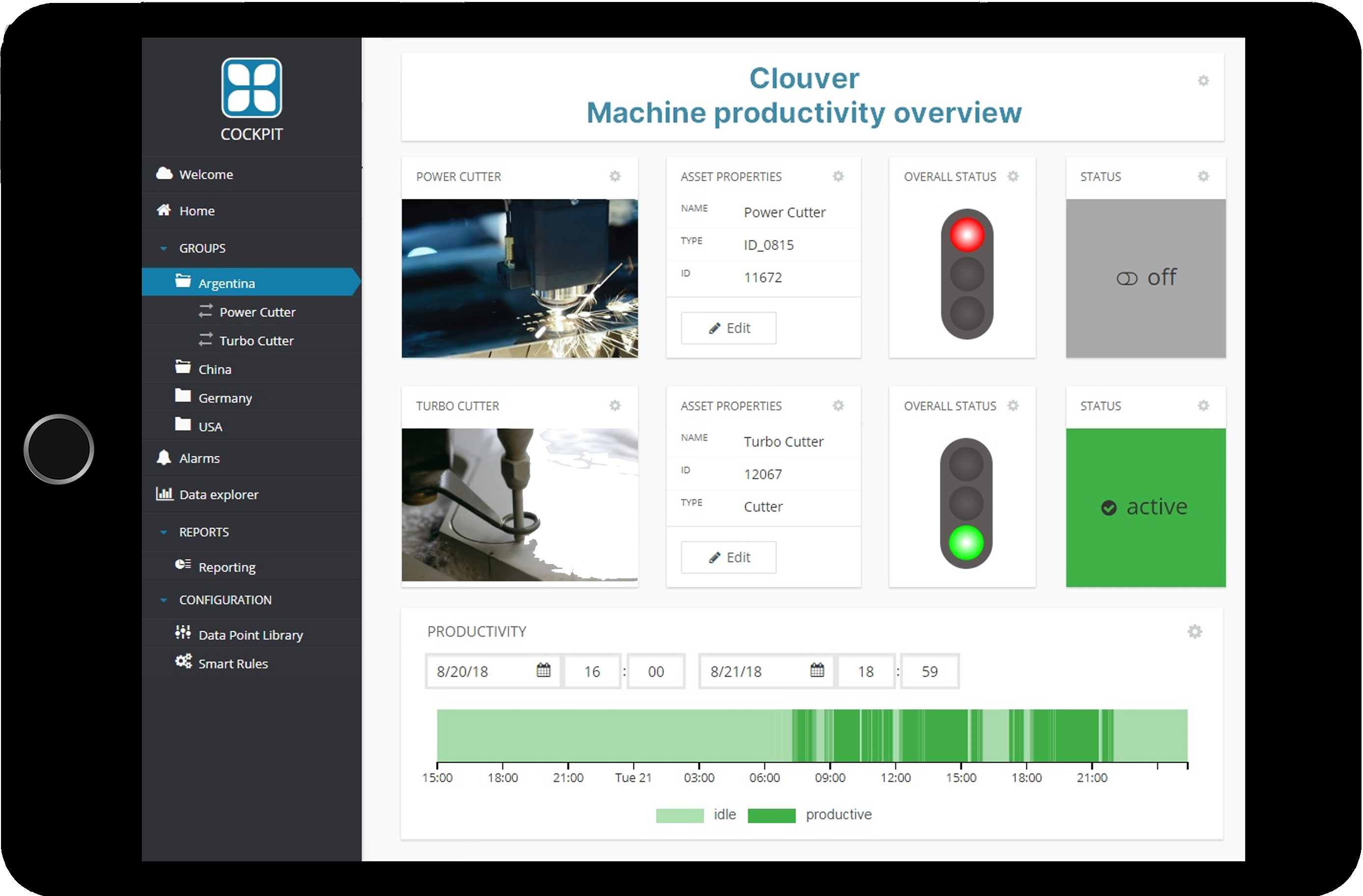

Customisable Dashboards

Immediately after connecting your machines to Clouver, you have access to all your machine data through a wide range of pre-built dashboards. These dashboards are fully customisable for you to tailor them to your specific requirements. This way, you see exactly the information and KPIs that are most crucial for you and your business.

Security First

We understand the importance of the security of your data and systems. Our IIoT solution integrates state-of-the-art security protocols to safeguard your data from threats. Additionally, in Clouver, you control internal access to machine data through the sophisticated rights management.

Digital and Sustainable

Thanks to the central overview of all your machines, you consistently monitor all your standstills and thus minimise your downtime significantly. In this way, you increase the productivity of your systems in the long term – in a simple, paperless, and user-friendly way for everyone.

Monitoring From Anywhere

With the cloud solution, you access all your machine information at any time and from anywhere around the world – even from your mobile device. This ensures you always have a real-time overview of your entire production, regardless of your location.

Made for Everyone

Clouver provides valuable information for improvement and facilitation of daily tasks to everyone in your company – both management and production managers, as well as machine operators.

Frequently Asked Questions

Which companies is Clouver made for?

Clouver is an IIoT production monitoring platform for manufacturing companies – regardless of the products you manufacture or the industry you operate in. You can connect both individual or a few machines, as well as entire machine parks. Clouver is equally suitable for small businesses just entering the world of Industry 4.0 and manufacturers with large production lines requiring comprehensive solutions.

Why should we employ an IIoT solution?

By implementing an IIoT solution, you identify optimisation potential for your production and sustainably increase your machine productivity. You benefit from numerous advantages that help you save costs and time in the long run and make decisions based on reliable information:

- Boost Your Machine Efficiency: Monitor and optimise industrial processes by transforming downtimes and failures into productive times.

- Make Data-Driven Decisions: Utilise extensive real-time data for precise planning and performance improvements.

- Reduce Hidden Production Costs: Predictive wear and maintenance analyses through sensors reduce downtime and significantly increase machine lifespan.

- Stay On Top of Your Production: With access to real-time data, you always have an overview of your manufacturing – accessible from any device, anywhere.

- Save Time, Time, and More Time: Implementing paperless order management saves considerable time by eliminating all your walking distances and manual working steps.

Can I connect the IIoT platform to my ERP system?

Absolutely! If an export from the ERP system via the MQTT network protocol is possible, integration occurs without additional steps. Otherwise, a SmartKit can establish an interface between the ERP system and Clouver.

Either way, we ensure a solution that brings data from your production planning and order management to your machines and transfers machine data collected with Clouver to your ERP system.

What data can be collected via the IIoT platform?

Clouver consolidates data from various areas:

- Your machines provide information about production, including:

- Status information

- Production events

(downtime, shift changes, number of produced parts, ...) - Availability and failure of machines

- Performance information on machines

- Quality information

(e.g., scrap capture).

- Your employees provide detailed information about:

- Failures

- Service activities

- manual steps.

- Overarching MES or ERP systems complete your overall view with data about:

- manufactured products

- materials used

- jobs

- planning information.

With Clouver, you centralise all this information, enabling you to use it in your production and for the management and optimisation of your manufacturing.

Are my data secure in Clouver?

Yes, your data is secure in Clouver. With our well thought-out security mechanisms to secure your data against loss, alteration, or third-party access, along with the sophisticated rights management in the Cloud, you can rest easily without any security concerns.

For more information on security and technical details, please refer to the Clouver Cloud FactSheet, available in the download section at the bottom of this page.

What hardware components, devices, and sensors are needed to collect relevant data?

The hardware can range from easy-to-use, non-invasive current measurement clamps and gateways with data interfaces to sensor packages customised for your machine. Typically, we use our SmartKit Gateways for this purpose. For considering the "human factor" in production, we additionally leverage the TouchPanels of our DowntimeAnalytics and Paperless solution. In any case, we provide you with the complete package.

Feel free to reach out – we are always ready to advise you on creating the optimal package to increase throughput in your production!

How long does the implementation of the IIoT solution take?

The implementation of Clouver is straightforward because we meet you right where you are in your journey to digitisation. We accompany you in the initial steps of digitising your bottleneck machine, through digitiasation and monitoring for your production line, to the digitisation strategy of your entire company. Initial steps are quickly implemented and realised; the key is to have a reliable partner for your further journey. We are happy to accompany you and walk through each of your individual steps with you.

What are the costs for using Clouver?

With Clouver, you have the option for a simple and cost-effective entry using the sandwich method: you assemble the composition you need from the components of our offer. The costs for use are very individual, depending on the type, age, and number of machines. Also, the costs vary depending on the specific solution you want to use. For example, if you want to make your production completely paperless, we recommend adding the Clouver Paperless option to the Clouver platform. Using only the Clouver SmartKit enables a simple and cost-effective entry into machine production monitoring.

Perhaps one of our regular offers is attractive for you? Subscribe to our LinkedIn channel to stay informed and not miss any promotions.

In general, you always receive an individual offer with all costs transparently presented. Just talk to one of our Clouver experts, and we will work with you to create an offer tailored to your requirements.

Is there an opportunity to test the IIoT platform for free?

Currently, we do not offer free testing, as such a test depends entirely on your wishes, requirements, and the available interfaces of your machines. To fully grasp the potential of Clouver and form your own impression, feel free to book our free and non-binding live demo using the offer below or contact us directly!

Typically, our customers start with small solutions tailored to their needs to get an initial understanding of the product and its benefits. Our experts work with you free of charge to develop a concept for the gradual digitisation of your production with Clouver, making it easy for you to enter the world of IIoT.

DOWNLOADS

This might also be of interest to you

Patrick Beer

Sales Manager IIoT

More Information? Reach Out to Us!

Learn more about our products, services, and potential collaboration. Simply get in touch with us by phone or email. I look forward to a personal exchange!

- Phone: +49 241 93681-500

- Email: contact@procom-automation.de